Agglomerated Stone Countertop Producing Videos

Agglomerated Stone Countertop Producing Videos

Agglomerated Stone from Superior Countertop combines natural elegance and resistance. Harder than natural stone, with a huge variety of colors to fit the style in the kitchen, bathroom. Manufactured from a mixture of pure quartz, aluminium sand(dolomite sand), pigments and resins. This product preserve all the technical and aesthetic characteristics of the original stone. but has been improved and enhanced, resulting in a product that is ideal for areas requiring high abrasion and scratch resistance, like Kitchen Countertops Vanity Tops, etc.....

But How are they produced?

Aghglomerated(aluminium & dolomite) Stone Slab Production

The natural quartz crystal minerals are carefully selected with high purity of SiO2 99.9%, without any harmful radioactive heavy metals, and bring brand-new healthy life.

Production Process

1: Feeding & Mixing

Step 1, Manual Selecting

Step 2, Sober & Deironing:

Use different screen elected required mesh of quartz sand and aluminium sand(dolomite- sand improve the purity of sand.

Step 3, Deironing

Blender / Mixer Raw materials are inspected, then fed into mixers and blended together.

2: Molding

Spreading: The skilled workers spread all the materials falling down from the Stirring Machine in the slab module.

3: Pressing

The slab is then compacted by a special vacuum and vibration process The stability of the product's performance depends on the tonnage of the press. In Sunrise countertops, we use 60 tons press to ensure the uniform of each square meter constituent structure can be more fastness.

4: Heat Curing

The aluminium stone slab are moved to the curing kiln, though the process of heat curing that gives them the ultimate strength and solidity.

5: Cooling

After heat curing, the aluminium stone slab be back-to-back and face-to-face, upright them in 90 °, and tightly clamp it, in case of the curled slab during the course of slab cooling in 24 hours.

6: Trimminging Edges, Leveling and Thicknessing

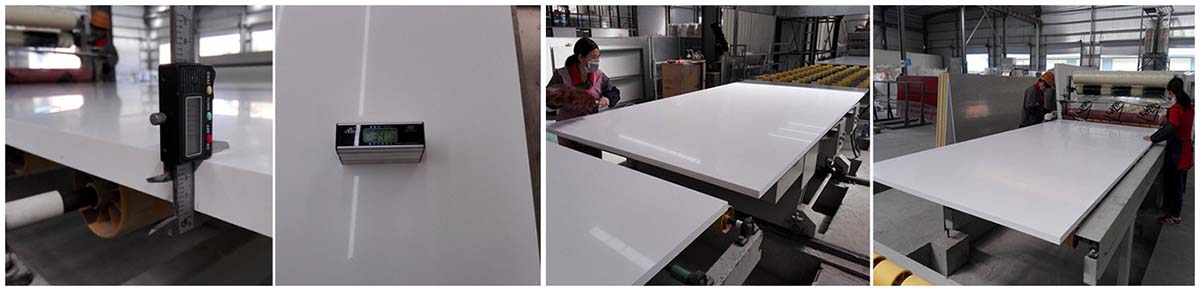

7: Quality Assurance & Film Covering

Quality control is very important. We select only the finest raw materials, which undergo an exacting series of production processes at our state-of-the-art manufacturing facilities. Each and every one of our finished products are polished to perfection, and ready to be rigorously examined.

Strong technical power, excellent quality management and after-sale service are our guarantees to customers. Strict production control, inter-procedure inspection, outgoing inspection for every product makes the best quality assurance. Contact Us, let us Superior Stone service your nest projects.

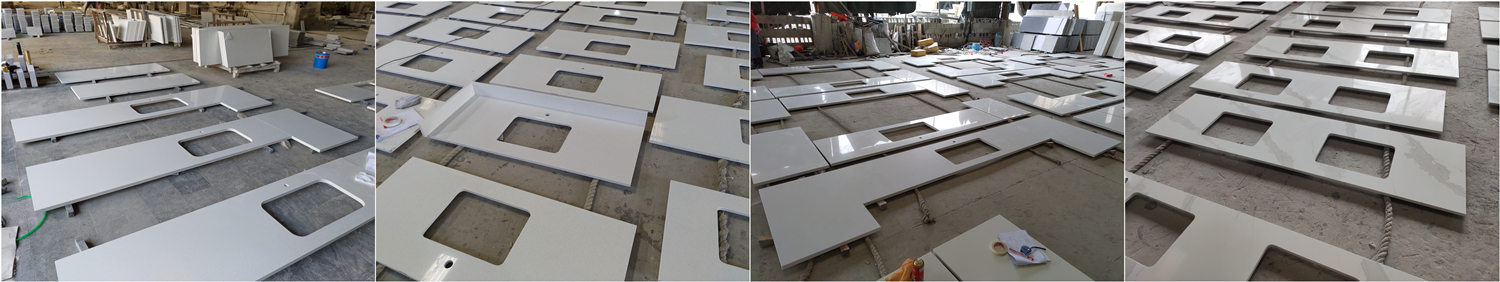

Each piece will be check by our professional QC with more than 10 years experience. And the inspection will be done five times from cutting, processing, packing, etc. We inspect step by step to make sure the quality, and we will directly make the failed one broken directly.

1. Check the drawing. We will make drawings quickly and check with you. We will not start to produce until you confirm and sign on it.

2. Check thickness. Thickness difference is not allowed.We will use technical calipers for checking the thickness correctly.

3. Check the edge. Edge polishing smoothly is necessary for kitchen and bathroom units.

4. Check the surfaces. No matter the front or back side, we check it, again and again, to make the surface clean and flat. Because no one will like it to be dirty even the back surface.

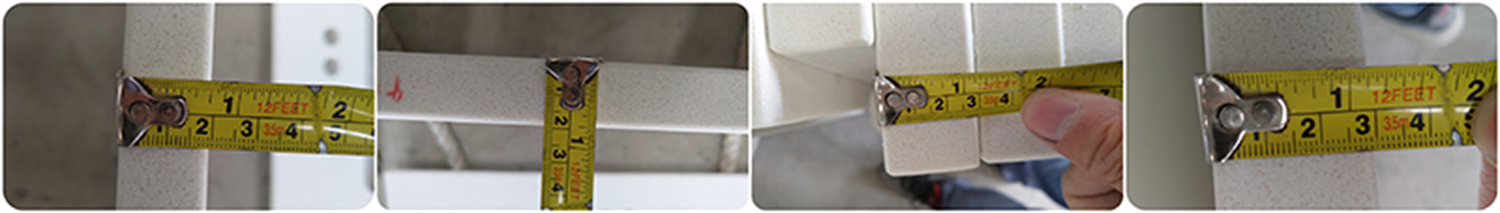

5. Check the cut-out hole. Size and shape for hole are quite important for installing sink and accessories. Dimension error is not tolerant even just 1mm.

6. Check the size. We are checking all details on kitchen units according to drawings, such as sink center size, faucet sink, front edge to sink edge size, etc.....will make the size totally same as required even it takes more time.

7. Check the backsplash. Evan backsplash is smaller than the countertop, it should not be ignored. Size, thickness and surface should check same.

8. Check the color difference.It will be embarrassed if there are two colors for same set.Don't worry. We will not make it happen. We pay lots of attention on kitchen seams,We promise to offer a perfect countertop without chromatic aberration.

9. Waterproof Lables. Each kicthen and bathroom piece will make a waterproof lable on edge to help customers to find the unit piece. This is necessary for cut to size projects.

10. Check the packing. Checking piece by piece before packing, our QC will make those qualified ones packed together. Then they will make a stamp on the wooden crates.

11. Check the loading. There is professional crew for loading. They will conduct how the crates should be put, which part should be strengthened with strips.

Of course, you are welcome to do an inspection with us. No matter how many quantities it is, we can check piece by piece together to help put those concerns to rest.